When purchasing a Genuine leather product, our initial assessment often begins with our sense of touch, as the texture plays a critical role in its appearance, feel, and application.

Insights

Leather goods are available in an infinite variety in the market, making the decision-making process challenging. From smooth to grainy, the texture significantly influences its overall look and use. This texture depends on the portion of the hide it originates from, the thickness and the type of tanning and finishing applied.

The way leather is graded is fairly straightforward; the skin is removed from the hide, leaving behind the leather surface. Imperfections are then eliminated before it undergoes tanning in the tannery. Post-tanning, a grader evaluates and grades the leather based on its quality.

Understanding these factors can greatly aid in discerning the different types and qualities of leather available, ensuring informed decision-making when choosing leather products.

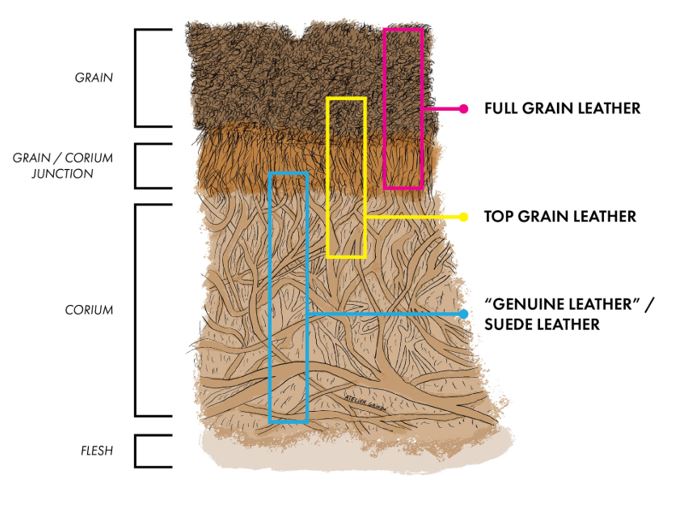

The Grain: the outermost layer of the hide, very high fiber density.

Grain/Corium Junction: the layer of skin that joins the grain and the corium, intermediate fiber density.

Corium: the last layer of skin before the flesh, very low fiber density.

When delving into the world of leather, one encounters various layers and types, each with distinct characteristics.

Full grain and top grain leather are high-quality types, sourced from the top layer of the animal hide. While full grain is unaltered, retaining its natural state, top grain undergoes a sanding process to remove imperfections.

On the other hand, split-grain leather is derived from the bottom part of the hide and possesses different traits, often being weaker than its full grain and top grain counterparts, with suede as the most common form.

Despite its appealing name, genuine or premium leather, comes from an intermediate section of the hide and lacks both the character of full grain leather and the softness of split-grain, requiring extensive processing for usability.

Lastly, bonded leather ranks as the lowest quality, comprising leftover scraps bonded together and typically found in inexpensive or less prominent leather products.

Using Full-Grain Leather for Making Bags

Full-grain leather, the topmost layer of the hide, is often treated with aniline dyes that preserve its natural appearance. Sometimes, semi-aniline dyes are used to apply a thin protective coat that helps prevent stains. The vertical fibers in full-grain leather make it exceptionally durable and resistant to peeling, cracking, puncturing, or tearing. Additionally, full-grain is moisture-resistant and becomes more beautiful with age, developing a stunning patina.

Pros of Full-Grain Leather:

- Unchanged Grain: The natural grain remains intact, offering an authentic look.

- Durable: Its high density of fibers makes it remarkably strong and long-lasting.

- Longevity: Full-grain leather has a longer lifespan due to its durability.

- Aesthetic Appeal: It boasts a natural look that improves with aging, developing a unique patina.

- Breathability: The preserved external pores make the leather more breathable.

Cons of Full-Grain Leather:

- Visible Imperfections: The natural grain means any imperfections or blemishes are visible.

- Cost: Full-grain leather is generally more expensive compared to other types.

- Sensitivity: It can be more sensitive to certain elements and requires proper care.

Using Top Grain Leather for Making Bags

Top grain leather comes from the second layer of the hide, beneath the topmost layer. The leather’s surface is sanded and buffed to eliminate defects, resulting in a more uniform look. However, this process makes top grain less durable and quicker to degrade than full grain leather. Despite its reduced durability, top grain is commonly used to produce high-quality goods because it is thinner, cheaper, and more pliable than full grain leather.

Pros of Top Grain Leather:

- Easy to Work with: Its pliability makes it easier to craft into various products.

- Consistent Finish: Sanding and buffing provide a smooth and uniform appearance.

- Long-lasting: It lasts longer than low-grade leather types.

- Can be Dyed: The leather can be dyed and designed to resemble exotic leather.

- Cost-effective: It is cheaper than full-grain leather.

- Uniform Look: Its uniform appearance, free of imperfections, allows for embossing into any grain.

Cons of Top Grain Leather:

- Reduced Durability: Missing the exterior grain with dense fibers makes it less durable.

- Less Breathable: It cannot absorb body oil, diminishing its breathability.

- No Patina Development: Unlike full-grain leather, it does not develop a patina over time.

- Potential to Crack: Without proper care, top grain leather may crack.

- Shorter Lifespan: It generally has a shorter lifespan compared to full-grain leather.

Using Split Leather for Making Bags

Split leather, derived from the corium or lower layer of the animal hide, remains once the top grain layer has been separated. It is more affordable than top grain leather and features a fibrous texture with reduced durability. Types of split leather include cross-grain and suede.

Using Cross-Grain Leather for Making Bags

Cross-grain is embossed leather, masking imperfections of the real hide. It retains its natural marks, with a soft and plushy texture achieved by prolonged processing in a running drum. The bubble appearance endears it to many bag enthusiasts.

Pros of Cross-Grain Leather:

- Soft

- Thick

- Durable

- Attractive

Cons of Cross-Grain Leather:

- Poor quality

- Tough to clean

- Flimsy

Using Suede Leather for Making Bags

Suede leather, with its fuzzy and soft underside, offers a unique appearance and feel. It is a type of split leather from the interior hide layer. Suede is valued for its pliability and softness, though it tends to trap oil, moisture, and dirt.

Pros of Suede Leather:

- Desirable look and feel

- Unique nap

- Durable

Cons of Suede Leather:

- Thin

- Less durable than other types

- Prone to damage and stain

Using Genuine Leather for Making Bags

Genuine leather, made from lower quality layers bonded with glue and painted for a uniform look, is the least quality of all genuine leathers. It is affordable and maintains a leather-like feel, despite being prone to stretch marks and degeneration over time.

Pros of Genuine Leather:

- Affordable

- Leather look and feel

- Easy to maintain

- Long-lasting with proper care

Cons of Genuine Leather:

- Prone to stretch marks

- Degenerating appearance

- Can feel hot and sweaty in summer

- Sellers may overcharge

Final Thoughts

Those final thoughts summarize the nuances of leather quality really well. Knowing the different grades—full-grain, top-grain, genuine, and bonded leather—it’s easier to balance between cost, durability, and appearance.

When deciding on leather for a project, it’s also helpful to consider what the item will be used for. For example, full-grain leather is excellent for items that need to be durable and develop a unique patina over time. Top-grain leather is the second-highest quality in the leather hierarchy, coming right after full-grain. It’s sanded and refinished to remove imperfections, giving it a smooth and uniform look. This makes it more resistant to stains compared to full-grain leather but also means it won’t develop the same rich patina over time.

However, the definition of quality can differ based on individual needs and preferences. For instance, opting for genuine leather can be a strategic choice if you aim to balance quality and cost. This approach allows manufacturers to use premium top-grain leather in visible areas while utilizing genuine leather in less prominent parts of the product. This not only helps maintain a competitive price point but also ensures that the essential components of the item meet high standards.

As you consider these options, it’s important to weigh these factors carefully. Understanding the distinctions between various leather grades empowers to make informed decisions that align with project requirements and budget. By taking the time to evaluate these choices, you can select the right type of leather that meets both aesthetic and functional needs.

Frontier introducing messenger bags made from high-quality leather, ensuring a sophisticated appearance and long-lasting durability. The rich texture adds a touch of luxury to your everyday work or travel essentials. Crafted from high-quality materials, our office messenger bag for men is built to withstand daily wear and tear, providing long-lasting functionality.

In conclusion, the Indian leather industry shows India’s resource richness and skilled labor force. Despite facing challenges, the sector has shown strength and continues to be a major part of the economy. With a focus on sustainable practices, innovative technologies, and quality improvement, the future of the Indian leather industry looks bright. As global demand for ethically produced leather goods increases, India is well-positioned to take advantage of new opportunities and achieve significant growth in the coming years.

Frontier Trade Link, which connect rural businesses with global markets, and the growing demand for saddlery products will play crucial roles in driving this growth and enhancing the industry’s global presence.

Add comment